HOME > NEWS

Choosing the suitable Brown Fused Alumina for the application is a problem.

1:Brown Fused Alumina is made of bauxite, coke and anthracite as raw materials and continuously melted at high temperature. It is characterized by few impurities, high purity, good crystal quality, unbreakable, firmness and improved friction.

2:Application:

Brown Fused Alumina is mainly used as abrasive manufacturing, refractory and sandblasting service.

3:Quality distinguish:

(1). The most direct way to judge the quality of Brown Fused Alumina is based on its Al2O3 content. The more Al2O3, the higher quality.

It is mainly divided into three grades: first grade95%、sub-first grade92%、second grade85% and third grade75%.

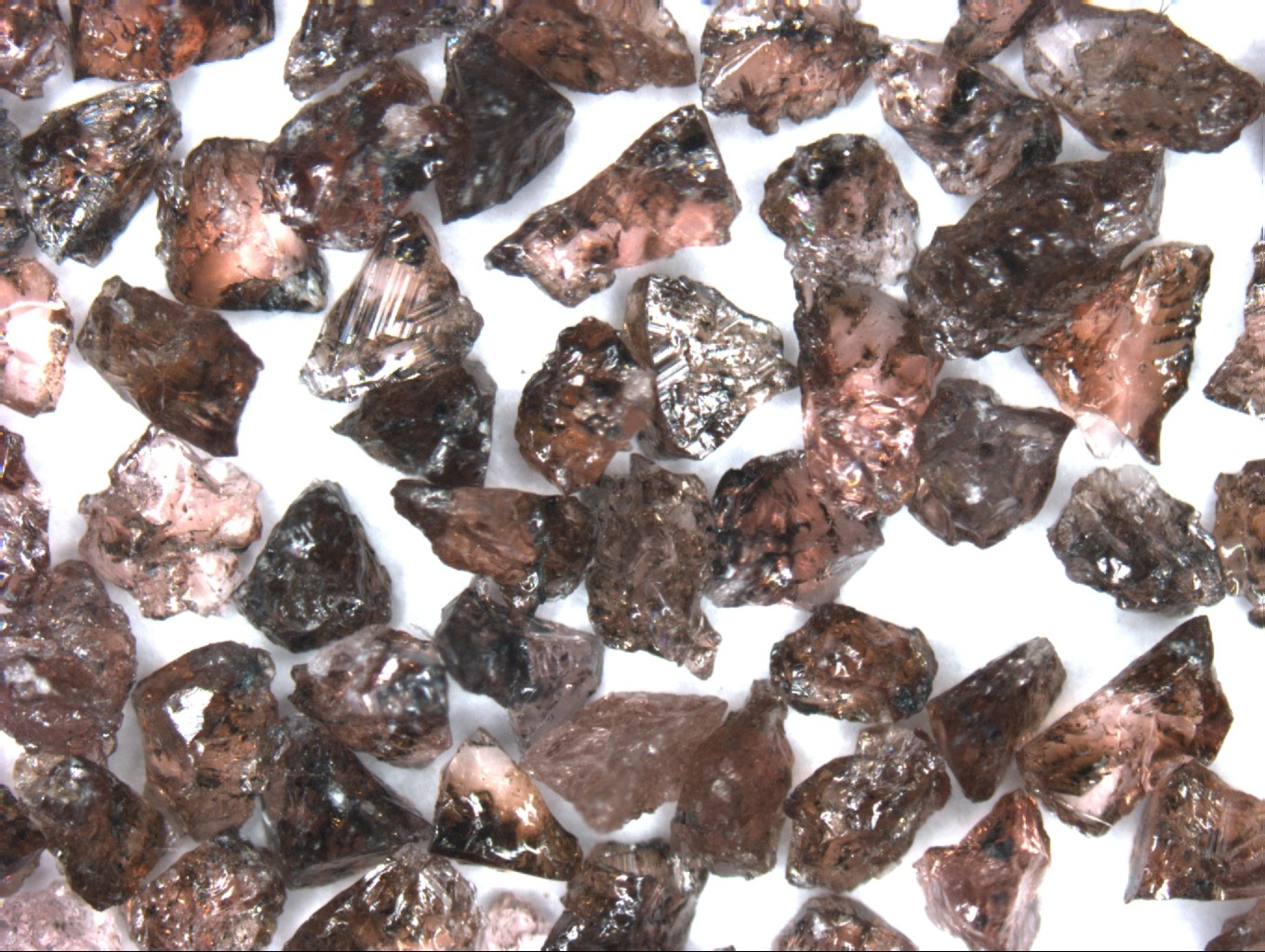

(2). Brown Fused Alumina is dark purple in color. It has high transparency, light transmission and brightness in sunlight. It has slightly higher hardness, higher abrasion resistance and higher Al2O3 content.

Attention! Dark, light-colored and opaque brown corundum abrasives are of poor quality and consume a lot when used.

(3). Brown Fused Alumina usually has good self-sharpening and toughness, and good Brown Fused Alumina depends on its original mineral content. Usually good primary minerals are dominated by small spherical particles with small particle size, high impact resistance, and smooth and bright surface.

4:Fixed or titling furnace

(1). The Brown Fused Alumina smelted in the spraying furnace is characterized by large crystal volume, small crystal volume, high glass quality, so the relative toughness is relatively poor, and the brittleness has been improved to some extent . The Brown Fused Alumina smelted by this method is suitable for resin abrasives and refractories.

(2). The Brown Fused Alumina smelted by fixed furnace has small crystal size, large crystal block and less glass. The brittleness is poor but the toughness is good and the wear resistance is not small. This method is suitable for the manufacture of vitrified abrasives.

When choosing Brown Fused Alumina products, users can choose different grades of products according to the actual field of use and the expected effect, so as to make full use of the products and use them reasonably.