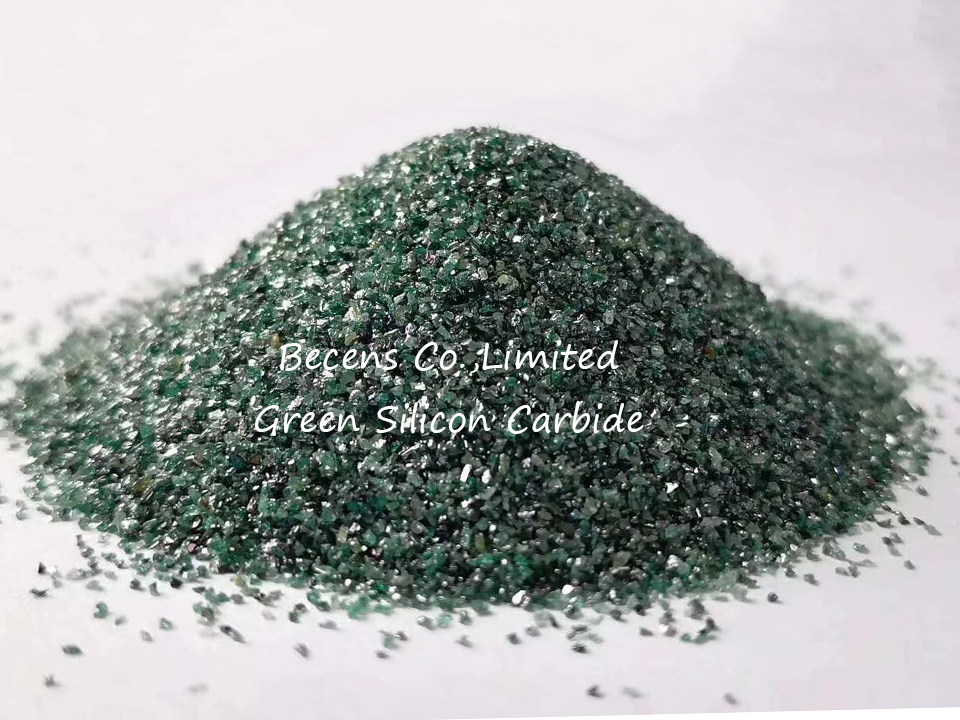

Green Silicon Carbide

Green Silicon Carbide (SiC) is an extremely hard (Mohs 9.4 / 2600 Knoop) man made mineral that possesses high thermal conductivity and high strength at elevated temperatures (at 1000°C, SiC is 7.5 times stronger than Al2O3). SiC has a modulus of elasticity of 410 GPa, with no decrease in strength up to 1600°C, and it does not melt at normal pressures but instead dissociates at 2600°C.

The production method of green silicon carbide powder is basically the same as that of black silicon carbide, but the requirements for raw materials are different. Green silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and is smelted at high temperature in a resistance furnace. The smelted crystal has high purity and high hardness, and its hardness is between alumina oxide and diamond. Mechanical strength higher than alumina oxide.

The production method of green silicon carbide is the same as that of black silicon carbide. It is formed at a high temperature of about 2200 °C. Green, translucent, hexagonal, with a higher Sic content than black. The smelted crystal has high purity and high hardness, and the hardness is between alumina and diamond. The mechanical strength is higher than that of alumina. The physical properties are similar to black silicon carbide, but the performance is slightly brittle than black, and it also has better thermal conductivity and semiconductor properties.

Green silicon carbide is suitable for processing cemented carbide, glass, ceramic and non-metallic materials, as well as semiconductor materials.

1. In the non-ferrous metal smelting industry. Green silicon carbide has high temperature resistance, high strength, good thermal conductivity and impact resistance.

2. In the steel industry. The corrosion resistance, thermal shock wear resistance and good thermal conductivity of green silicon carbide improve the service life of large blast furnaces.

3. Processing of metallurgical ores. Green silicon carbide has strong wear resistance, and its hardness is second only to diamond. is the ideal material.

4. It is used in the building materials ceramic grinding wheel industry. Using its characteristics, thermal conductivity, heat radiation and high temperature strength, a slab kiln is made. It can not only reduce the capacity of the kiln, but also improve the installed capacity and product quality of the kiln, and shorten the production cycle. It is also ideal for indirect material sintered ceramic glaze baking

Standard sizes:

F12 to F220;

F240 to F2000

#240 to #4000, JIS240 to JIS4000;